One effective solution for mitigating EMI is the use of EMI gaskets. These conductive materials create a barrier against EMI and are widely used in electronic product design. However, selecting the right EMI gasket and properly integrating it with other aspects of electronic product design, such as thermal management, can be complex. In this FAQ, we will answer 10 common questions related to EMI gaskets, providing you with reliable information and data to help you make informed decisions about using EMI gaskets in your electronic product designs.

One effective solution for mitigating EMI is the use of EMI gaskets. These conductive materials create a barrier against EMI and are widely used in electronic product design. However, selecting the right EMI gasket and properly integrating it with other aspects of electronic product design, such as thermal management, can be complex. In this FAQ, we will answer 10 common questions related to EMI gaskets, providing you with reliable information and data to help you make informed decisions about using EMI gaskets in your electronic product designs.

- What are EMI gaskets and how do they work?

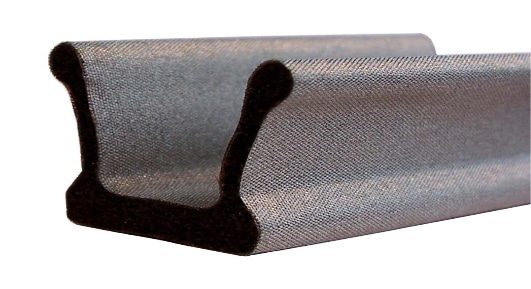

EMI gaskets are conductive materials used to create a barrier against electromagnetic interference (EMI) in electronic products. They work by creating a conductive seal between two metal surfaces, which blocks the transmission of EMI. - What types of EMI gaskets are available and how do they differ?

There are several types of EMI gaskets available, including finger stock gaskets, conductive elastomers, wire mesh gaskets, and conductive foam. Each type differs in terms of its performance, cost, and suitability for different applications. - When should I consider using an EMI gasket in my electronic product design?

EMI gaskets should be considered whenever EMI is a concern in electronic product design, particularly in applications where regulatory compliance is required. - What are the benefits of using EMI gaskets in electronic products?

The benefits of using EMI gaskets include improved EMI shielding effectiveness, increased product reliability and durability, and compliance with regulatory requirements. - How do I select the right EMI gasket for my electronic product design?

The selection of the right EMI gasket depends on several factors, including the EMI frequency range, the level of shielding effectiveness required, the size and shape of the mating surfaces, and the operating environment. - What are some common challenges associated with using EMI gaskets in electronic products?

Common challenges associated with using EMI gaskets include managing the cost of the gasket material, achieving optimal compression for maximum shielding effectiveness, and ensuring that the gasket does not interfere with other aspects of product design, such as thermal management. - How do I properly install an EMI gasket in my electronic product design?

Proper installation of an EMI gasket involves ensuring that the gasket is compressed to the correct level, that it is installed in a clean and dry environment, and that it is securely fastened to prevent movement or dislodgement. - Can EMI gaskets be customized to fit my specific electronic product design needs?

Yes, EMI gaskets can be customized to fit specific product design needs, such as specific mating surface shapes, operating environments, and shielding requirements. - How do EMI gaskets compare to other EMI shielding options, such as conductive coatings or ferrite beads?

EMI gaskets offer several advantages over other EMI shielding options, including greater shielding effectiveness, more consistent performance, and greater ease of installation. - Are there any industry standards or regulations that apply to the use of EMI gaskets in electronic products?

Yes, there are several industry standards and regulations that apply to the use of EMI gaskets in electronic products, including the Federal Communications Commission (FCC) regulations and the International Electrotechnical Commission (IEC) standards.